Benefits of Best Predictive Techniques to Improve Reliability in Industry

Successful implementation of a new practice is a challenge. Requires enthusiasm and a positive attitude of workforce and leadership, strategic framework, and culture of excellence-Culture of Reliability.

Key factors influence the Industrial profits

– Assets- O&M, Process etc.,

– Materials

– People- Management, Workforce

Asset- An electronic or mechanical hardware component or device, a software product, or a manufacturing system or process. The probability that an asset or item will perform its intended functions for a specific period under stated conditions.

Best Predictive Maintenance Practice of Asset leads to

> Lowest Downtime

> Highest Uptime

> Zero Breakdowns

> Highest OEE (%)

> Low cost to ERV/RAV ratio

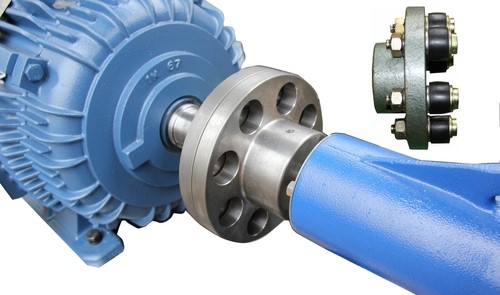

To achieve above and to improve plant reliability one of the best techniques is Predictive Maintenance of Assets through Vibration Monitoring helps to identify the health condition and to improve Overall Equipment Effectiveness(OEE) and Total Equipment Efficiency Performance(TEEP) and Zero Breakdowns.

Remote Vibration monitoring in Industry 4.0 by IoT

The Fourth Industrial Revolution or Industry 4.0 is the ongoing transformation of traditional manufacturing and industrial practices combined with the latest smart technology. The remote vibration monitoring of assets to assess the health condition.

“The Internet of Things is simply “A network of Internet connected objects able to collect and exchange data.” It is commonly abbreviated as IoT. In a simple way to put it, you have “things” that sense and collect data and send it to the internet.”

A network of IoT collects data and stores in secure place to view and analyze the asset performance remotely.

original image ? or new infographic

Predictive techniques has an objective of

Predicting the future trend of asset condition, trend analysis, and preselected thresholds.

To determine at what point in future maintenance activities should be scheduled.

Allowing corrective actions to be improved through proactive planning and scheduling.

Allowing preventive actions to be optimized by avoiding traditional calendar or run-time directed schedules.

Benefits of Predictive Techniques and Remote Monitoring

Reduces unscheduled downtime and maintenance shutdown costs.

Improves manufacturing process reliability & equipment reliability.

Improves business by reducing maintenance unit cost and RAV.

Schedule compliance and improves overall KPI.

Live secure data display to monitor round the clock around the world.

Trending and remote expert analysis.

Goal of Predictive Techniques and Remote Monitoring

Adoption can result in substantial cost savings and higher system reliability and shows effect on cost, time, and production rate.

Estimated statistics – Reduction in maintenance Costs: 15-35%

Reduction in Downtime: 20-40%

Increase in Production: 15-30%